Upgrading unit refines biogas into pure biomethane

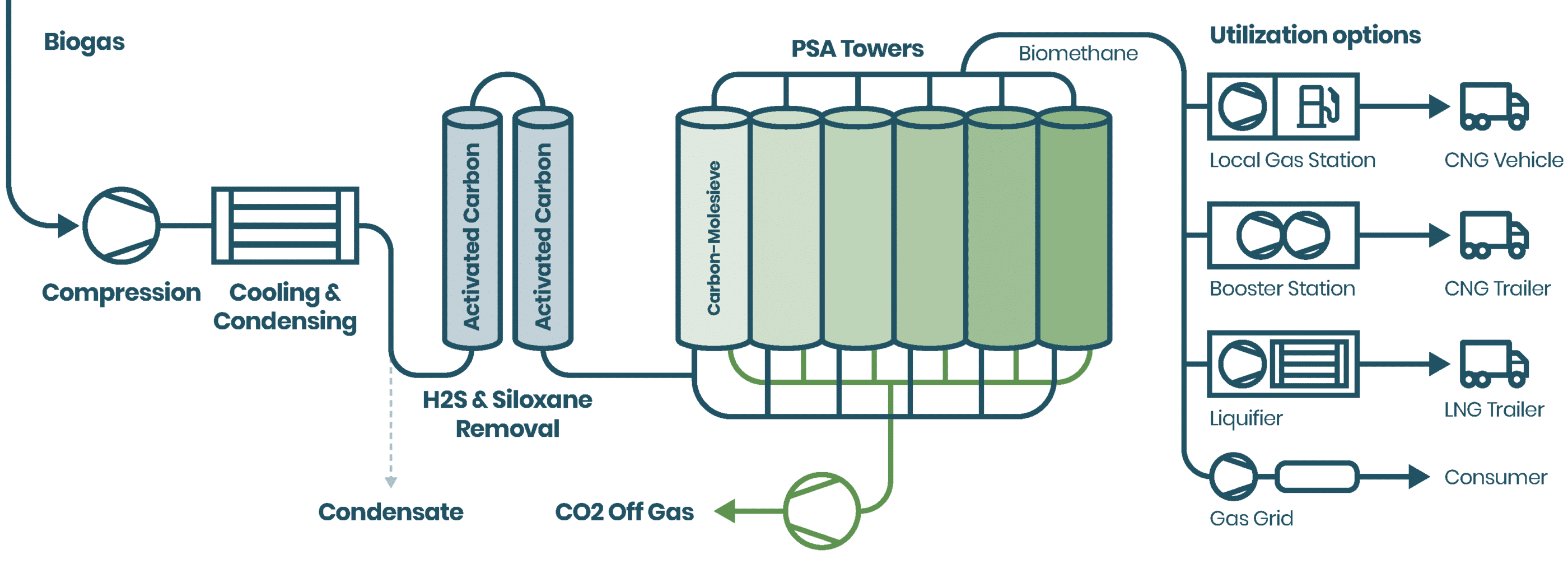

In addition to methane, raw biogas typically contains about 35-40 % carbon dioxide, as well as small amounts of water, nitrogen, oxygen and impurities. For biogas to be used, for example in heavy transportation, most of these gases must be removed before being pressurized and used as transport fuel. It means that the gas treatment is needed.

Biogas upgrading unit is a solution to produce high-quality biomethane out of raw biogas. Upgraded biomethane is similar to natural gas and it can be used as vehicle fuel and injected into the natural gas grid.

BIOupgradeCH4 biogas upgrading system is an automatic, easily monitored and remotely controlled refining system, that utilizes membrane technology from world’s leading membrane supplier, Air Products. BIOupgradeCH4 enables efficient gas upgrading to over 99 % methane content.

With the reliable membrane and PSA upgrading technologies represented by Biovoima, even the highest gas quality requirements are met without any chemical or water utilization.

Request for Quotation