Comprehensive solution for municipal waste utilization in energy production

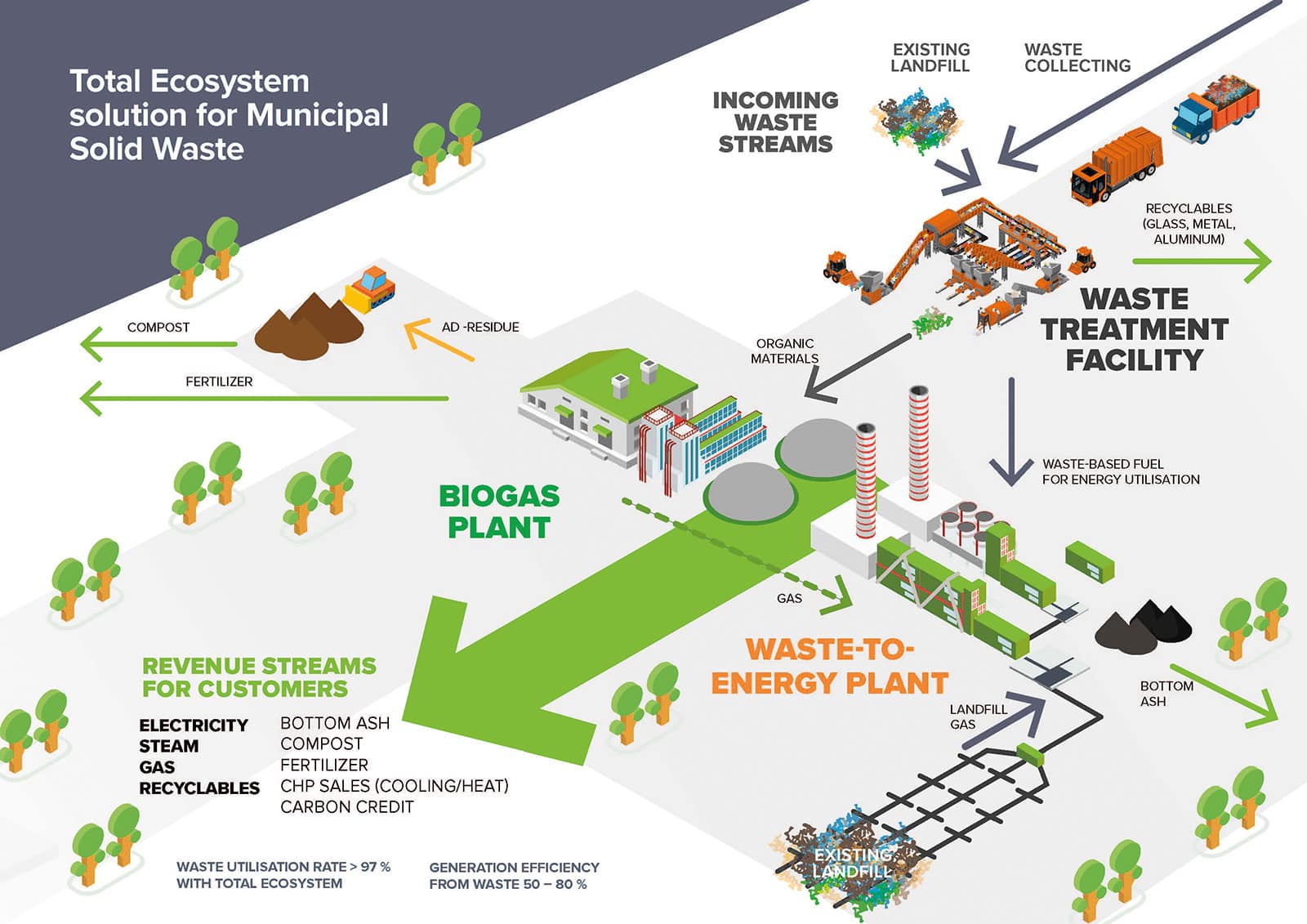

Biovoima is part of a business cluster whose network builds state-of-the-art and efficient plant ecosystem for energy utilization from mixed waste and energy waste. The plant modules are individually tailored to each project according to the amount and composition of the waste and the project objectives, but the typical process is described below.

In developing countries, typically 50-70 % of all municipal waste (MSW, Municipal solid waste) is organic waste that decomposes in landfills into methane and escapes into the atmosphere. Emissions are huge, as the amount of waste in highly urbanized cities can be tens of thousands of tons a day. Some studies have estimated that landfills are one of the world’s largest single sources of greenhouse gases. At the same time, a great energy potential is lost from the point of view of the recovery of both organic and inorganic waste.

The greatest benefit of the ecosystem is in these markets, where separate collection of waste is not yet widely practiced. Instead of landfilling, the ecosystem solution makes it possible to separate and treat different waste streams in the most appropriate way. The final products are energy, recycled products, fertilizers and soil improvers.