![Explore the key terms of biogas industry! Biogas glossary, part 2/2 [M-W]](https://biovoima.com/wp-content/uploads/2020/07/Suomen-Biovoima_Biogas_glossary_m-w_header.jpg)

TS, VS, OFMSW, mesophilic and thermophilic… The language of biogas professionals is teeming with dozens of terms and abbreviations that may not be understandable to those who are interested in the biogas subject. We want to help you navigate! Explore the second part of key concepts of biogas industry and stay on track of the bioenergy terms. We have listed the expressions and abbreviations in alphabetical order below.

Mesophilic process

Digestion at normal atmospheric pressure (about 1 bar) and a temperature of about + 35°C.

Nm3

Normal cubic meter, i.e. cubic meter of gas at normal pressure and 0°C. Unit of gas volume.

OFMSW (Organic fraction of municipal solid waste)

Organic material in waste stream originating from households. In many countries, despite government efforts to collect organic household waste separately, the amount of organic material in municipal solid waste (MWS) in Europe is still significant. Although full of impurities such as plastics, metals etc., OFMSW is quite valuable when the organics and inorganics are separated.

After separating the organics, the dried inorganic material (RDF or refuse-derived fuel) remains. This fraction is often used for incineration. Retrieving both RDF and organic waste from MSW allows to yield more energy from the fraction in the form of biogas and alternative energy.

Percolation liquid

In anaerobic digestion, nutrient-containing liquid released from the feedstock in garage type dry fermentation plant, which can be recycled back to the reactor as an inoculum. Recirculation of the percolation liquid ensures the circulation of microbes, regulates the moisture balance, decomposition and gas production of the fermentation process.

PPA (Power Purchase Agreement)

A long-term purchase agreement in which an energy company, as an electricity user, agrees to purchase a certain amount of electricity from an electricity producer at a contract price, for example for 10-20 years. The PPA can be fixed-price or variable (e.g. based on stock exchange pricing). or a biogas project to be profitable, there must be a customer for the electricity (as well as heat) produced with CHP plant. In a biogas project, the PPA brings predictability and stability.

Pre-treatment

Treatment of waste to reduce its harmfulness, facilitate its treatment or enhance its recovery. In a biogas project, pre-treatment equipment separates non-biodegradable waste such as plastic, glass, sand and metal from the waste mixture and crushes the biomass to a more uniform composition.

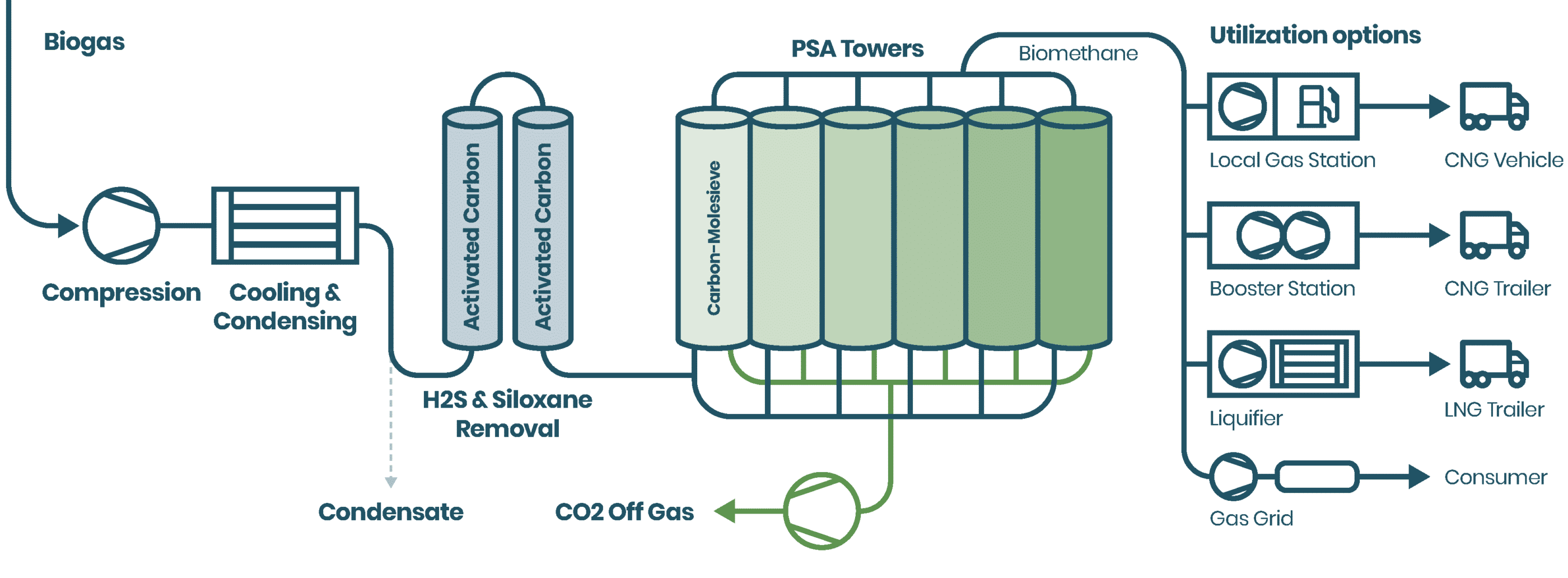

PSA (Pressure swing adsorption)

One of the gas processing techniques, which takes advantage of the ability of gases to pass through a particular material under pressure and thus separates gases of different permeabilities. In other words, the adsorbent (typically activated carbon) absorbs the carbon dioxide of the raw gas at one pressure and releases it at another. The PSA gas upgrading process usually has four or more columns in parallel. At least one column is in the adsorption step, one in the desorption step, and in two other columns the pressures are either lowered or increased. The methane content of the upgraded gas is more than 97%.

Purified gas

Gas treated for heat and electricity generation purposes by removing contaminants that damage the generator and cause harmful emissions. Impurities are poison to the CHP unit’s gas engine. It should be mentioned that biomethane often refers to purified gas.

Raw gas

Gas from a landfill or natural gas source. Raw gas is often upgraded or purified in a gas treatment plant before further usage.

Reject water

Nitrogen and potassium-containing liquid fractions of the separated digestate. The reject water can be used as soil conditioner or as fertilizer, if the biogas plant’s raw materials are of plant and animal origin. The reject water can also be recycled from the end of the reactor to its beginning, acting as an inoculum.

Thermophilic process

Digestion at normal atmospheric pressure (about 1 bar) and a temperature of about + 55°C.

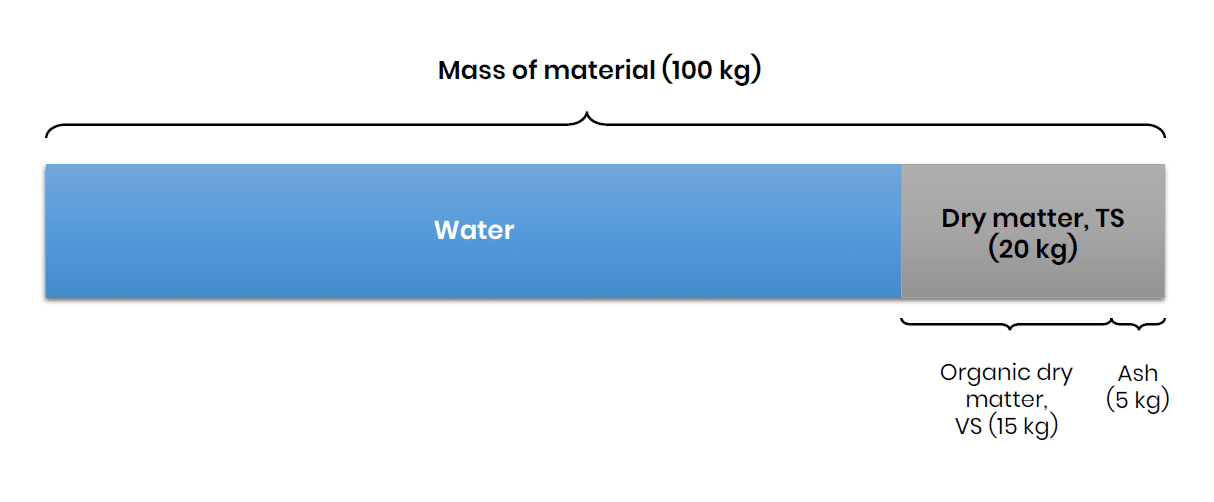

TS (Total solids)

After removal of the liquid, the remaining dry matter content of the feedstock, including both inorganic (i.e. ash) and organic material. The abbreviation DM (dry matter) is also used. TS is one of the most important quality features of the feedstock. It is expressed as a percentage.

Upgraded gas

Gas that is treated for use in transport sector or other pressurization, liquefaction or injection to the gas grid by reduction of impurities in the raw gas. Carbon dioxide, sulfur compounds and siloxanes are removed, for example, by passing them through the activated carbon filters of the gas upgrading unit which extracts the impurities.

All gas supplied to Finland’s national gas grid is upgraded: natural gas is upgraded in Russia and biogas is upgraded in Finland.

VS (Volatile solids)

The part of organic material in the dry matter (i.e. in TS). The abbreviation oDM (organic dry matter) is also used. VS is one of the most important quality features of the feedstock. It is expressed as a percentage.

Waste-to-Energy (energy recovery)

Waste incineration in which the energy content of municipal and other waste is converted into heat and/or electricity. In Finland, heat is utilized mainly in the district heating network. Only non-recoverable waste is sent to incineration.

![Explore the key terms of biogas industry! Biogas glossary, part 2/2 [M-W]](https://biovoima.com/wp-content/uploads/2020/07/Suomen-Biovoima_Biogas_glossary_m-w_header-300x157.jpg)