BAT (Best Available Technology)

In order to protect the environment, in accordance with the BAT principle, the best available technology for the environment must be used at the various stages of the biogas process. BAT is mentioned in the Environmental Protection Act (Section 5) and its observance is required according to the environmental permit.

Biofuels blending mandate

Policy on the promotion of the use of biofuels in transport. Obliges transport fuel distributors to supply a certain minimum proportion of biofuels for consumption each year. In other words, it obliges companies selling fuel to blend more biofuel into petrol and diesel every year. In 2020, the EU’s renewable energy obligation for the transport sector is 10%. In Finland, the biofuels blending mandate is 20%, and it applies to both diesel and petrol.

Biomass

An organic substance that can be used, among other things, in energy production. In other words, biomass is the feedstock to be processed in a biogas plant for biogas production.

Capacity

Power at which a plant can (at its highest) produce or consume energy.

CBG / CNG

CBG = Compressed Biogas. CNG = Compressed Natural Gas. When used as transport fuel, biogas or natural gas must be pressurized to 200 bar before refueling the vehicle.

Usually CNG or transport gas serves as a general term for gas refueled in a vehicle without specifying whether it is biogas or natural gas. The use of natural gas (CNG) as a transport fuel reduces CO2 emissions by about 25% compared to petrol, but using biogas (CBG) reduces greenhouse gas emissions by about 85%.

CHP (Combined heat and power)

Combined heat and power production using biogas, natural gas or landfill gas. Cogeneration achieves higher efficiencies than separate production (up to more than 85%), i.e. the fuels used in energy production can be used more efficiently.

Composting

Aerobic digestion of solid organic waste material by microbes under controlled conditions. Composting is a convenient way to treat biowaste in your yard, following the instructions given by a composter manufacturer.

Cryogenic separation

One of the gas processing techniques that utilizes the different boiling points of compounds in biogas. The upgraded gas from the process is liquid biomethane (LBG). Liquid carbon dioxide is also obtained as a by-product, which can be used, for example, as a refrigerant for refrigerated vehicles.

Digestate (Digested residue)

The material remaining after the anaerobic digestion of an organic feedstock. The digested residue has a significant value as a fertilizer material after the anaerobic digestion in a biogas plant. Digestate can be utilized as such, or its dry fractions can be for example pelletized, and its liquid fractions can be further enriched. The utilization of digestion residue as fertilizer depends on the feedstocks used in a biogas plant and the local legislation.

Digestion (Anaerobic digestion, Biogasification)

Decomposition of biodegradable material by microbes under anaerobic conditions. The end product of such anaerobic digestion is biogas and the by-product of the process is digestion residue, i.e. digestate, that can be separated into dry and liquid fractions for further use.

Dry digestion

Treatment of waste with high dry matter content (TS > 15%). In a biogas project, high loading rate of the dry digestion process ensures high usability and gas production per cubic meter of reactor volume. Dry digestion allows to handle challenging feedstocks in the biogas process as it is less susceptible to contamination than the wet digestion process, where difficult feedstocks can cause floating and sedimentation challenges.

Feedstock

Organic material fed to and treated in the biogas plant. Typical feedstocks suitable for biogas production are organic fractions of municipal solid waste (OFMSW), spoiled food, loss fodder from arable farming, livestock manure, slaughterhouse waste and sewage sludge. If the microbes in the biogas plant do not receive “food” (feedstock), biogas production will decline.

Feedstock mix

A mixture of different feedstocks in a suitable ratio that is treated in a biogas plant. Good feedstock mix can balance out ammonia and nitrogen content of the feedstock. This has added value in by-products further utilization. For example, it can increase the possibility of using the digested residue as a fertilizer.

Feed-in tariff

A fixed-term guaranteed price, higher than the market price, paid by the state to the electricity producer for electricity produced from renewable energy, including biogas. The feed-in tariff system closed for new biogas plants in Finland on 1 January 2019.

FSA (Feedstock supply agreement)

An agreement between the producer of the raw materials and the raw materials handler for the supply of the raw materials. Continuous supply of organic feedstocks is basically the foundation for the optimal operation of the biogas plant. If raw materials are missing or not enough for the optimal operation of the plant, steady biogas production is interrupted. In this case, income is difficult to estimate and project profitability may suffer. So access to feedstocks must be secured by a long-term feedstock supply agreement.

Gas processing technique

Generic name for techniques used to enrich the methane content of biogas. The main purpose of gas processing technologies is to capture carbon dioxide from biogas, which is the second most common gas in biogas, and to convert it into pure biomethane. Gas processing/purification techniques include physical absorption (water scrubbing, organic physical scrubbing), chemical absorption (amine scrubbing), physical adsorption (PSA technology), membrane separation, and cryogenic separation.

GPA (Gas Purchase Agreement)

A long-term purchase agreement according to which a gas network company agrees to purchase a defined amount of gas from a gas producer at a contract price, for example for 10-20 years. In a biogas project, a gas purchase agreement brings profitability to the project as it secures a continuous flow of income.

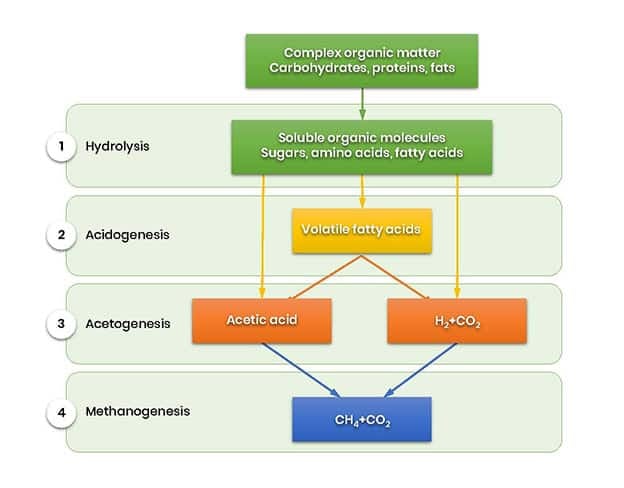

Hydrolysis

The first stage of anaerobic digestion process, which occurs through enzymes formed by bacteria. Bacterial enzymes break down complex organic substances (such as carbohydrates, proteins, and fats) into sugars, amino acids, and fatty acids.

Hygienization

Legally instructed one-hour heat treatment to kill harmful bacteria at + 70°C. Hygienization kills most pathogens such as salmonella and coliforms. If the end product of a biogas plant, i.e. digestate, is utilized commercially, for example as a fertilizer, then the law obliges to sanitize the material used in the reactor.

Inhibitors

Factors that cause a slowdown in microbial activity (i.e. a decrease in methane production) or, in the worst case, stop the entire digestion process. For example, ammonia (e.g., in chicken manure), hydrogen sulfide formed during sulfate reduction, and some metals are factors that inhibit methane production. Inhibitions can be prevented by avoiding process overload and diluting the feedstock material with non-inhibitory materials.

Inoculum

A reusable bacterial community, for example digestate from a functioning biogas reactor, intended to maintain the microbial community of another biogas plant. Inoculum is used to start-up a new biogas reactor.

Mesophilic process

Digestion at normal atmospheric pressure (about 1 bar) and a temperature of about + 35°C.

Nm3

Normal cubic meter, i.e. cubic meter of gas at normal pressure and 0 °C. Unit of gas volume.

OFMSW (Organic fraction of municipal solid waste)

Organic material in waste stream originating from households. In many countries, despite government efforts to collect organic household waste separately, the amount of organic material in municipal solid waste (MWS) in Europe is still significant. Although full of impurities such as plastics, metals etc., OFMSW is quite valuable when the organics and inorganics are separated.

After separating the organics, the dried inorganic material (RDF or refuse-derived fuel) remains. This fraction is often used for incineration. Retrieving both RDF and organic waste from MSW allows to yield more energy from the fraction in the form of biogas and alternative energy.

Percolation liquid

In anaerobic digestion, nutrient-containing liquid released from the feedstock in garage type dry fermentation plant, which can be recycled back to the reactor as an inoculum. Recirculation of the percolation liquid ensures the circulation of microbes, regulates the moisture balance, decomposition and gas production of the fermentation process.

PPA (Power Purchase Agreement)

A long-term purchase agreement in which an energy company, as an electricity user, agrees to purchase a certain amount of electricity from an electricity producer at a contract price, for example for 10-20 years. The PPA can be fixed-price or variable (e.g. based on stock exchange pricing). For a biogas project to be profitable, there must be a customer for the electricity (as well as heat) produced with CHP plant. In a biogas project, the PPA brings predictability and stability.

Pre-treatment

Treatment of waste to reduce its harmfulness, facilitate its treatment or enhance its recovery. In a biogas project, pre-treatment equipment separates non-biodegradable waste such as plastic, glass, sand and metal from the waste mixture and crushes the biomass to a more uniform composition.

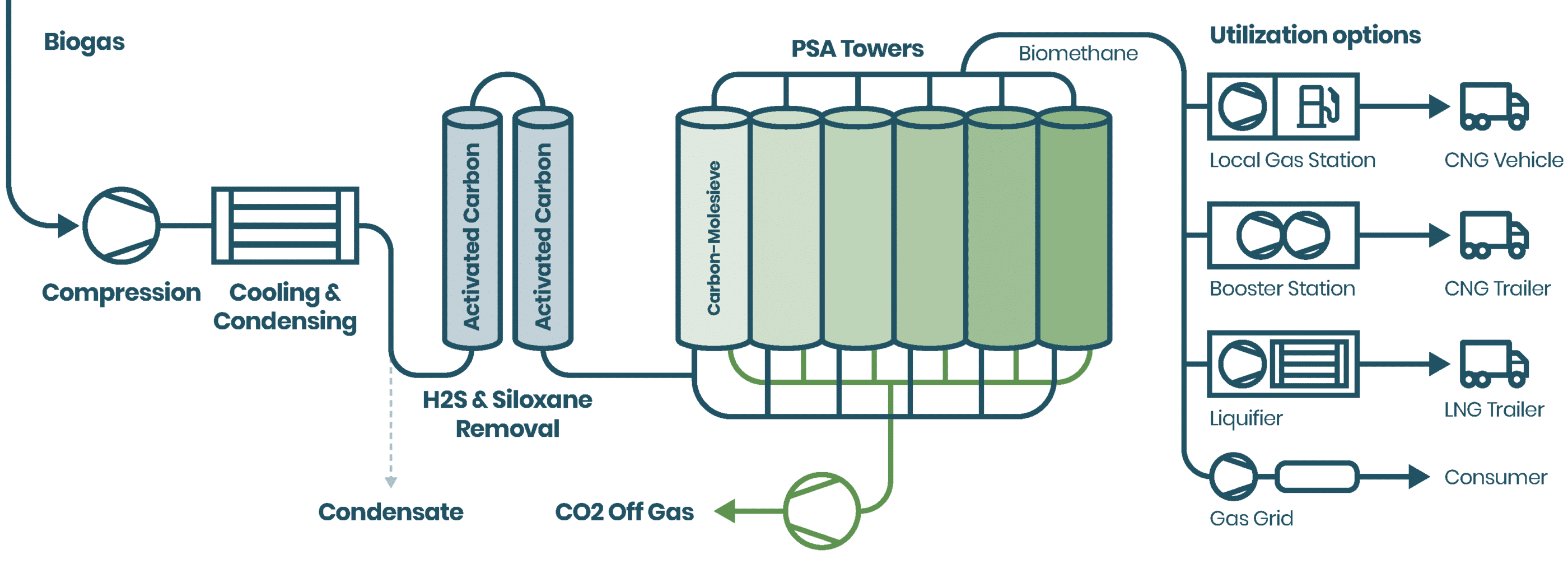

PSA (Pressure swing adsorption)

One of the gas processing techniques, which takes advantage of the ability of gases to pass through a particular material under pressure and thus separates gases of different permeabilities. In other words, the adsorbent (typically activated carbon) absorbs the carbon dioxide of the raw gas at one pressure and releases it at another.

The PSA gas upgrading process usually has four or more columns in parallel. At least one column is in the adsorption step, one in the desorption step, and in two other columns the pressures are either lowered or increased. The methane content of the upgraded gas is more than 97%.

Purified gas

Gas treated for heat and electricity generation purposes by removing contaminants that damage the generator and cause harmful emissions. Impurities are poison to the CHP unit’s gas engine. It should be mentioned that biomethane often refers to purified gas.

Raw gas

Gas from a landfill or natural gas source. Raw gas is often upgraded or purified in a gas treatment plant before further usage.

Reject water

Nitrogen and potassium-containing liquid fractions of the separated digestate. The reject water can be used as soil conditioner or as fertilizer, if the biogas plant’s raw materials are of plant and animal origin. The reject water can also be recycled from the end of the reactor to its beginning, acting as an inoculum.

Thermophilic process

Digestion at normal atmospheric pressure (about 1 bar) and a temperature of about + 55°C.

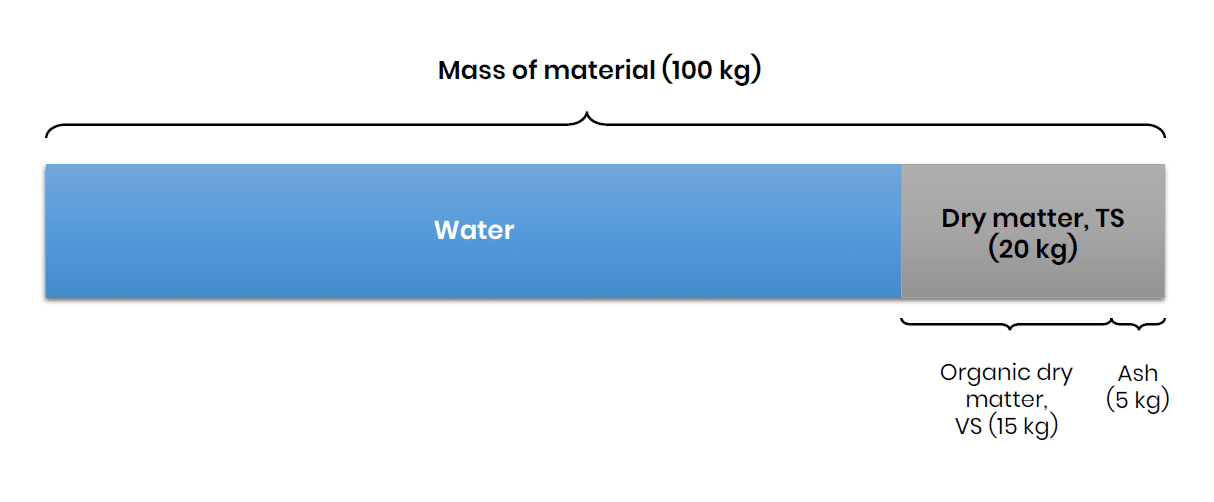

TS (Total solids)

After removal of the liquid, the remaining dry matter content of the feedstock, including both inorganic (i.e. ash) and organic material. The abbreviation DM (dry matter) is also used. TS is one of the most important quality features of the feedstock. It is expressed as a percentage.

Upgraded gas

Gas that is treated for use in transport sector or other pressurization, liquefaction or injection to the gas grid by reduction of impurities in the raw gas. Carbon dioxide, sulfur compounds and siloxanes are removed, for example, by passing them through the activated carbon filters of the gas upgrading unit which extracts the impurities.

All gas supplied to Finland’s national gas grid is upgraded: natural gas is upgraded in Russia and biogas is upgraded in Finland.

VS (Volatile solids)

The part of organic material in the dry matter (i.e. in TS). The abbreviation oDM (organic dry matter) is also used. VS is one of the most important quality features of the feedstock. It is expressed as a percentage.

Waste-to-Energy (energy recovery)

Waste incineration in which the energy content of municipal and other waste is converted into heat and/or electricity. In Finland, heat is utilized mainly in the district heating network. Only non-recoverable waste is sent to incineration.