Biovoima will supply a safety solution, a biogas and biomethane injection system and a gas compressor station for Frevar KF's biogas plant in Fredrikstad, Norway. The solutions are required both for the upgrade of the existing equipment and for the expansion of production at Frevar's biogas plant. The flare and compressor station will be commissioned by Biovoima in autumn 2026. Frevar has operations in waste management, drinking water production and wastewater treatment.

A flare is a critical safety device in biogas and biomethane plants. It safely burns excess or unusable biogas to prevent dangerous pressure build up and to reduce methane emissions when the gas cannot be used or upgraded. Biogas production is continuous, but gas consumption or upgrading is not. A flare ensures that when storage is full or equipment is offline, excess gas can be safely destroyed instead of building up pressure in the system.

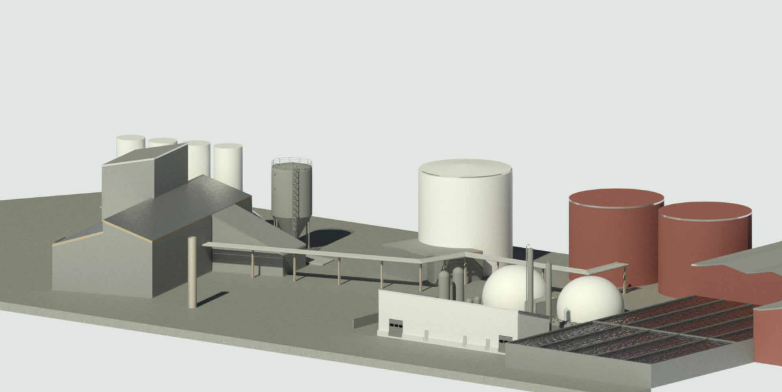

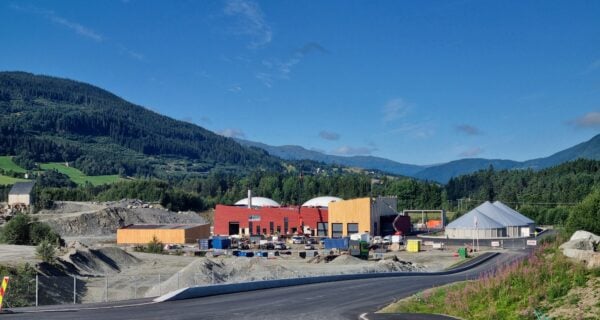

Gas compressors are essential in biomethane plants, because gas is produced at very low pressure and must be compressed for refueling, storage, transportation, or injection to the grid. Frevar KF, part of Fredrikstad municipality in Norway, is now upgrading their existing biogas production. A new biogas upgrading plant is now under construction, which can handle larger gas capacity in the future and therefor more high-pressure compressors for biomethane is needed.

Frevar produces about 4 million m³ of raw biogas annually in Fredrikstad plant from food waste and sewage sludge by receiving food waste from the food industry and households, and the sludge fraction comes from treating the wastewater of residents in the municipality of Fredrikstad. Biogas yields approximately 2.5 million m³ of upgraded biogas of vehicle fuel quality, biomethane. The gas is sold as fuel for buses, waste collection trucks and other gas powered vehicles. Some of the gas is also used by industrial companies in the Øra area.In addition to capturing the gas, the fully digested sludge becomes a soil improving product rich in nutrients, which can be returned to agriculture to grow new crops.

FREVAR KF owns and operates the municipality's wastewater treatment, water production, energy recovery and waste management process plants. Service production is divided into commercial activities and municipal responsibilities.

Fredrikstad aims to reduce its greenhouse gas emissions by 60% by 2030, and biogas production is one of the most effective tools to reach this goal. Biogas offers a “triple benefit”: it solves the challenge of organic waste management, produces renewable energy, and generates nutrient rich biofertilizer. Both biomethane and biofertiliser replace fossil based resources, providing a double climate benefit. While reducing waste generation is the top priority, some organic waste is unavoidable. By converting these unavoidable by products into biogas, the need for fossil carbon is reduced — addressing one of the root causes of today’s carbon imbalance.

More information on the project:

Jani Kangasaho, Sales Director, Partner

+358 50 468 7907, jani.kangasaho@biovoima.fi

"*" näyttää pakolliset kentät

© 2026 Biovoima

Privacy policy