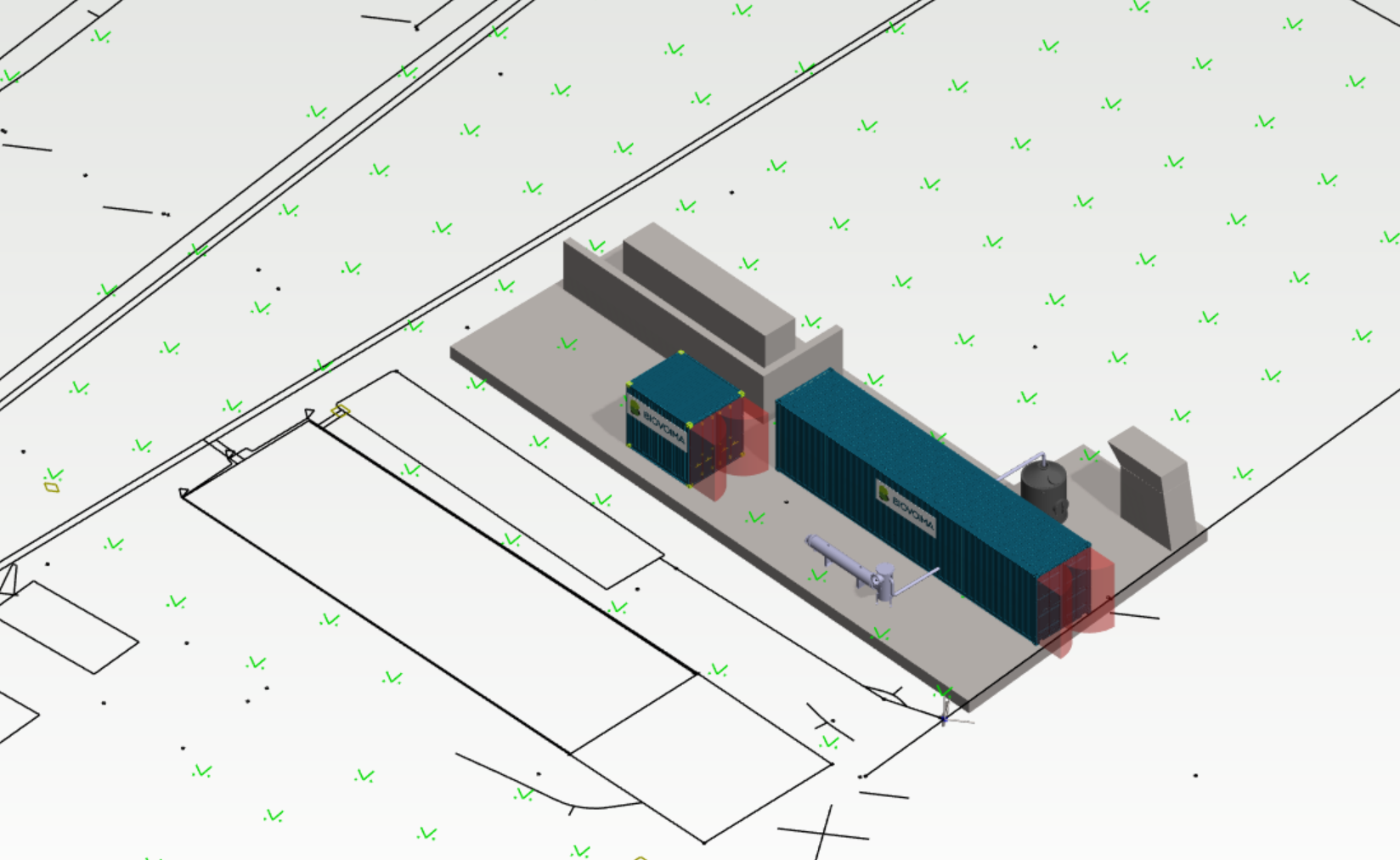

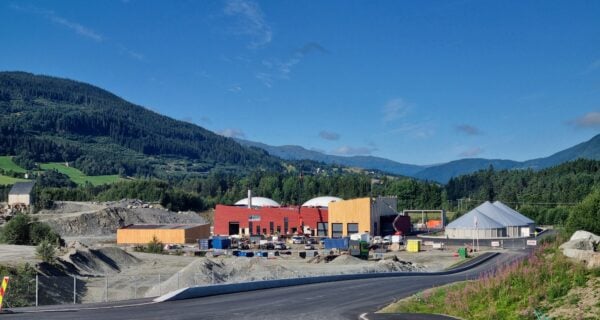

Latvian waste management company SIA ZAAO has ordered a BIOupgrade gas upgrading unit and a biomethane filling station, BIOpark, from Biovoima.

The project will be carried out in cooperation with the construction company SIA Rubate. Biovoima's project team has started the basic design of the project, with on-site installation scheduled for December 2025.

ZAAO Development Director Mārtiņš Niklass welcomes the cooperation with Biovoima.

”The cooperation with Biovoima has started in a positive and efficient atmosphere. We trust Biovoima's expertise in biogas processing technology and professional project execution. We look forward to continuing our partnership during both the implementation and commissioning phases.”

ZAAO invests in fossil-free fuel production in its own operations and uses the biomethane produced in its waste collection vehicles to reduce greenhouse gas emissions for a cleaner climate. Mārtiņš Niklass sees several advantages in this investment.

”ZAAO's investment in biogas processing and biomethane refuelling technology reflects its long-term commitment to environmental sustainability, operational efficiency and energy self-sufficiency. The transition to locally produced biomethane will enable ZAAO to reduce greenhouse gas emissions, lower transportation fuel costs and reduce dependence on fossil fuels.”

Biomethane is a much cleaner fuel than fossil fuels. It produces significantly less carbon dioxide emissions and thus helps to reduce the carbon footprint of waste management operations. In some cases, biomethane can reduce CO₂ emissions by up to 80-90 % compared to conventional fossil fuels. By using green fuel, ZAAO is leading the way in the waste management sector in Latvia.

”This project supports the company's aim to lead the green transition in the Latvian waste management sector”, says Niklass.

Own biomethane production and BIOparkCH4-fuel station ZAAO can significantly reduce the transport costs of waste trucks. With the introduction of the new solutions, waste trucks will no longer have to drive far to refuel, but will be able to refuel on their own premises. At the same time, ZAAO can reduce its dependence on fossil fuels, the price of which can fluctuate dramatically.

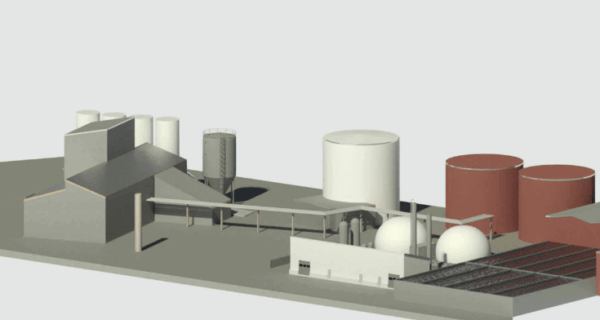

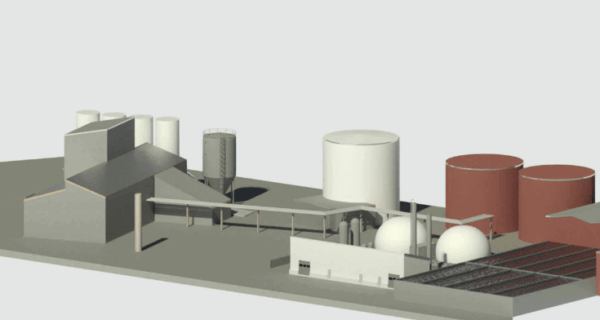

Biovoima BIOupgradeCH4-gas processing unit uses membrane technology to separate carbon dioxide and biomethane based on their different permeabilities. The gas is purified in three stages, where the gas is recirculated in the process. This achieves high end product quality and minimal methane loss.

BIOupgradeCH4 refinery unit is an automated, easily monitored and remotely controlled system that produces high-quality biomethane from raw biogas.

SIA ZAAO provides quality waste management services - collection, sorting, transport, treatment and disposal of waste in an environmentally friendly way, as well as communication and training.

SIA ZAAO is a public company owned by 11 municipalities: Alūksne, Balvi, Cēsis, Gulbene, Limbaži, Madona, Saulkrasti, Sigulda, Smiltene, Valka and Valmiera.

For more information:

Jani Kangasaho | Sales Director, Partner

jani.kangasaho@biovoima.fi | +358 50 468 7907

Evald Pärni | Sales Manager, Baltics

evald.parni@biovoima.fi | +372 501 2238

"*" näyttää pakolliset kentät

© 2026 Biovoima

Privacy policy