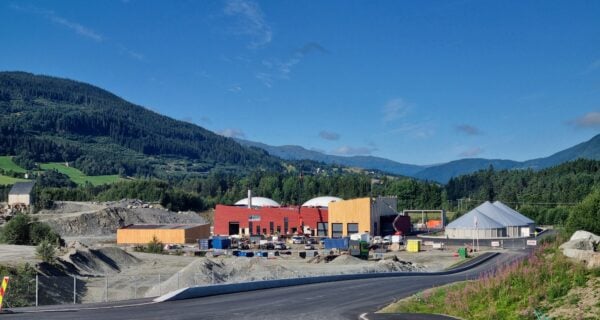

The need and demand for processing biogas into biomethane is very high throughout Europe and also in the Biovoima market area in the Baltic States, Poland and the Nordic countries. New BIOupgradeCH4 the biogas refinery unit responds to this demand with its agility and cost-efficiency. Demand is growing rapidly due to the green energy transition and the abandonment of Russian natural gas.

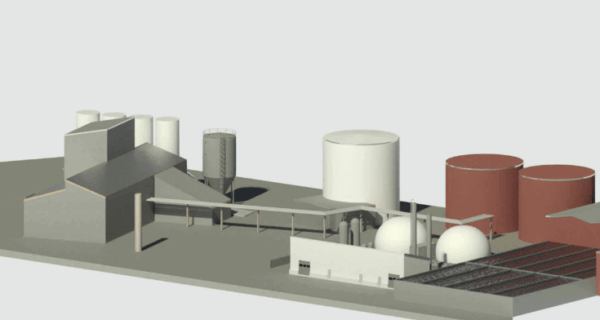

BIOupgradeCH4 the biogas refinery unit processes raw biogas into clean biomethane suitable for the natural gas network, industry and transport. Biovoiman BIOupgradeCH4 gas processing system is an automated, easily monitored and remotely controlled processing system that utilises membrane technology from Air Products, the world's leading membrane supplier. BIOupgradeCH4 enables efficient gas processing up to methane concentrations above 99%.

Biovoiman Managing Director Eero Tilsalan says that its own product will improve the production and supply security of biogas processing equipment for customers. ”We are excited about our new competitive biogas refining solution, which will enable us to more quickly meet the high demand for biomethane and also its quality. When processing biogas into ready-to-use biomethane, the pre-treatment of the gas prior to refining plays a very important role in the quality of the final product. The pre-treatment process removes e.g. hydrogen sulphide and other impurities as part of the refining process. This commonly known challenge has been taken into account in the BIOupgradenCH4 in the design and therefore the solution is suitable for different starting requirements, where the amount of impurities may vary significantly depending on the raw materials used for biogas production,” Tilsala adds.

Membrane is a biogas upgrading method in which the gas to be purified flows through hundreds of thin, spaghetti-like tubes. Carbon dioxide and methane are separated by their different permeability. The purification process is usually a two- or three-stage process, i.e. the gas is recycled within the process. This achieves a high quality end product and low methane loss.

Biovoiman BIOupgradeCH4 are professionally designed to meet customer needs and requirements, says Biovoima's Product and Development Manager Toni Hiltunen. ”The refinery unit can be tailored not only to process biogas into biomethane, but also to feed the gas into the natural gas grid. BIOupgradeCH4 can be integrated with Biovoiman BIOadapterCH4–to the online account. In this case, the refinery unit will process the biogas to the level required by the network, and measure the quantity and quality of the gas, while ensuring the monitoring and invoicing of the biomethane produced,” adds Hiltunen.

To ensure the best possible utilisation and decades of life, Biovoima provides scheduled maintenance of equipment and, if necessary, remote support for equipment operation.Biovoima provides maintenance of its solutions with its own expertise and also ensures that spare parts are available on time, up to 24/7 on-call services.

Eero Tilsala, Managing Director

+358 40 514 7047

eero.tilsala@biovoima.fi

Mikko Bengts, Sales Manager

+358 50 549 0882

mikko.bengts@biovoima.fi

"*" näyttää pakolliset kentät

© 2026 Biovoima

Privacy policy