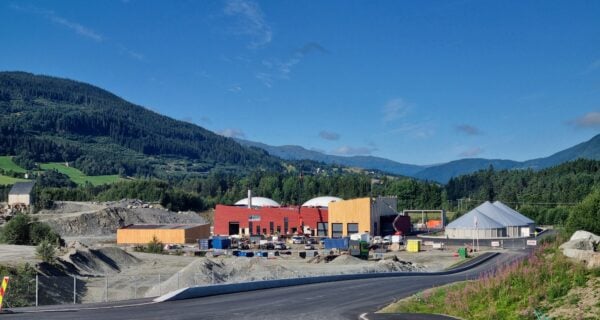

Biovoima supplies BIOadapterCH4 -pressure reduction unit for Hycamite in Kokkola, Finland. Hycamite is currently building a hydrogen production plant, which is expected to be completed during autumn 2024. BIOadapterCH4 required for the plant's gas receiving station.

Like Hycamite, the BIOadapter can be used as a gas pressure reduction unit at the point of use, but also for feeding biomethane into the gas network. Hycamite's Technology Concept Manager Mathias Ukskoski explains that the BIOadapter is intended to enable the reception of biomethane from gas transmission equipment, thus ensuring the continuous availability of gas and further the security of production of the plant. BIOadapterCH4 enables the integration of biomethane and natural gas into the plant's production process by reducing the gas pressure at the gas reception point, thus allowing the use of high-pressure gas imported by containers.

”Our plant uses biomethane in a production process that uses thermocatalytic decomposition of methane molecules to produce energy-efficient clean hydrogen and industrial-grade solid carbon by decomposing methane using emission-free technology. The end product is clean hydrogen for industrial use, as well as clean, high-value carbon that can be used as such in a wide range of industries. The coal is also further processed into graphite, which is important for the automotive industry, for example in the production of lithium-ion batteries,” says Ukskoski.

Biovoima's technologies are designed for biomethane and biogas plants, but the transformation of the energy sector and the green transition will extend the use of the same technological solutions to other gas-based industrial and energy production sectors. One of these is the booming hydrogen production.

Biovoiman Managing Director Eero Tilsala sees the BIOadapter supplied to HycamiteCH4 -solution as an exciting new example of industrial production involving the use of renewable energy and biomethane, as well as efficient innovation. ”Customizability is already a basic premise for our products, but we are ready to respond quickly through product development to new opportunities that the green transition will bring us, for example in the field of hydrogen production,” says Tilsala.

Biovoima is a turnkey technology supplier and integrator, and main contractor for new and modernisation plant projects for biomethane and biogas. Biovoima also provides maintenance and operation services for plants as well as logistics and distribution solutions related to biomethane.

Hycamite produces clean hydrogen and industrial-grade solid carbon by decomposing methane using emission-free technology. Our process is based on thermocatalytic decomposition (TCD) of methane molecules, i.e. we decompose methane using our catalyst and heat. Hycamite's pyrolysis technology requires only 13% of the energy needed to produce hydrogen by electrolysis. Hycamite's solution enables the creation of carbon sinks, providing customers with industrial-grade carbon suitable for applications such as lithium-ion batteries, composite materials and filters.

Eero Tilsala

Managing Director, Finnish Biovoima Oy

+358 40 514 7047

Mathias Ukskoski

Technology Concept Director, Hycamite TCD Technologies Oy

+358 40 541 0960

"*" näyttää pakolliset kentät

© 2026 Biovoima

Privacy policy