Finland's Biovoima Oy and Weeefiner Oy have agreed to collaborate on the manufacture and commercialisation of a completely new type of critical metals recovery system. The solution will be used in a wide range of industries from mining to wastewater treatment, and the circular economy benefits are at best very significant.

Biovoima is carrying out the implementation design and ongoing manufacturing of an industrial-scale test facility for Weeefiner. In the future, the cooperation will be extended to the commercial side.

- I see the cooperation model as an excellent one, as we have strong expertise in the design and manufacture of modular, containerised process equipment. In addition, the solution fits perfectly into our existing product portfolio and our customer base, where I believe it will generate a lot of interest. At the same time, the configuration will bring a nice additional workload to our production side, describes Biovoiman CEO Eero Tilsala.

Weeefiner is a company born in the Department of Chemistry at the University of Jyväskylä. Since 2017, its founders have been developing a revolutionary technology to recover precious metals such as gold from process and wastewater, as well as rare earth metals such as neodymium, which is important for wind turbines and electric motors. The technology can also remove harmful metals from, for example, mining side streams that would otherwise either go unrecovered or end up polluting the environment.

The solution is based on 3D-printed filters selective for a specific element, to which the elements dissolved in water bind. Chief Technology Officer at Weeefiner Elmeri Lahtinen says that the world's demand for critical metals is constantly increasing, but reserves themselves are dwindling or production is concentrated in countries that may limit international availability. Therefore, their re-use is important.

- For example, gold, silver, platinum and palladium can be recovered from the side streams of e-waste treatment with our catcher. WEEE will soon be the world's largest growing waste stream and has huge circular economy potential, especially for rare metals, explains Lahtinen.

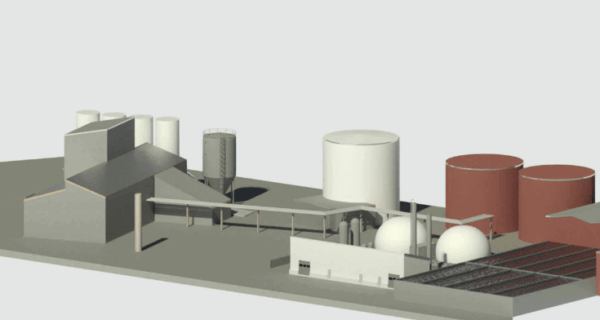

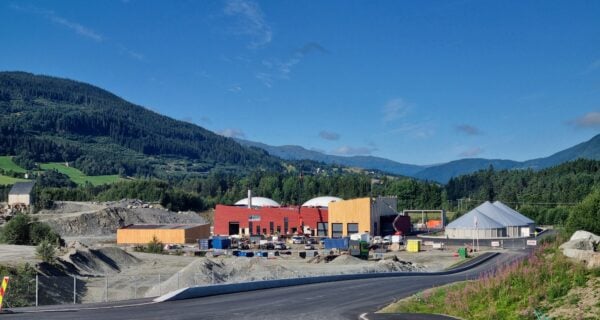

The industrial-scale testing equipment now being built is a containerised solution that can be easily transported to the customer's site, where the water and materials to be separated are located. The assembly will take place in Jyväskylä, Finland, and the equipment will be ready during May.

- The product is designed so that the test reactors can be modularly interchanged according to the customer's process water characteristics. This will allow the optimal separation efficiency to be determined before the customer builds and delivers their own industrial-scale equipment, which will hopefully be commissioned for a pilot run in a large number of tests., says the technology manager responsible for the design and manufacturing process Toni Hiltunen Biovoimalta.

The aim is to have the equipment touring around Finland this summer to test fluid flows.

- One of the advantages of the product is that although its core technology, the 3D filters, are technically state-of-the-art, they are still reasonably cheap to manufacture. Thus, the payback periods for industrial-scale custom installations will certainly be attractive for many projects., illustrated by Tilsala from Biovoima.

If you are interested in a test drive, please contact us and let's talk more!

Elmeri Lahtinen

Weeefiner Oy, Chief Technology Officer

+358 40 559 2666

elmeri.lahtinen@weeefiner.fi

Eero Tilsala

Finnish Biovoima Oy, Managing Director

+358 40 514 7047

eero.tilsala@biovoima.fi

Elsewhere on this topic:

Keskisuomalainen: ”Jyväskylä-based Weeefiner and Finland's Biovoima partner to develop critical metals recovery technology”

Technology & Economy: ”Recovering gold, platinum and palladium from water streams - a Finnish company has developed a 3D printable material for metal recovery”

University of Jyväskylä: ”Jyväskylä-based WeeeFINer provides a significant solution to a global problem - Unifund and Hanki Development as investors”

Purchasing & Logistics: ”WeeeFINer filter captures critical metals”

"*" näyttää pakolliset kentät

© 2026 Biovoima

Privacy policy