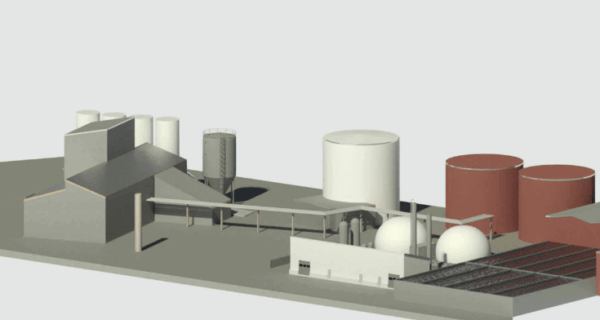

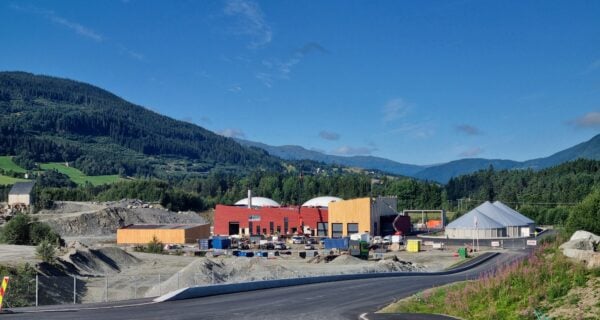

The commissioning phase of the biogas plant commissioned by Pieksämäen Vesi Oy and contracted by Biovoiman is almost complete and the plant is fully operational. The biogas plant will use organic sludge from Pieksämäen Vesi's wastewater treatment plant as raw material and produce biogas from it. This means that environmentally friendly energy will be produced from the wastewater in the Pieksämäki area for beneficial use, making the Pieksämäki central treatment plant self-sufficient in energy.

When it reaches full capacity, the Pieksämäki biogas plant will process 6 000 tonnes of sewage treatment plant sludge and grease trap sludge per year. The population of the economic area served by the plant is about 17 000. The biogas produced is used to produce 100 % of renewable electricity and heat for the wastewater treatment plant's own needs, with the excess energy being fed into the electricity and district heating networks.

We interviewed Tero Kemppi, Project Engineer of Biovoima and Matti Laakso, Managing Director of Pieksämäki Vesi, about the Pieksämäki biogas plant.

At full capacity, the biogas plant will produce about 1.8 GWh of energy, roughly split in half between electricity and heat. About one third of this will be used for the biogas plant's own energy needs, the rest for the central treatment plant.

We have been a turnkey supplier for the project. This is usually an easy and low-risk model for the client, as we have the overall responsibility for meeting the requirements of the tender.

The project started in April 2022, a few months behind the original schedule due to wartime automation procurement, but surprisingly few delays were encountered.

In practice, yes. If we are talking about a smaller sewage treatment plant that does not have enough sludge to meet the feedstock requirements of the smallest viable biogas plant, part of the sewage sludge can be replaced by other organic feedstocks, such as slurry.

Often, the key to the profitability of small biogas plants is that the energy produced can be used for its own purposes, i.e. it can be used as a substitute for existing purchased energy. The cost of receiving external inputs, i.e. gate fees, also contributes to the profitability of the plant. Of course, the fertiliser benefit from the end product also provides a backstop to profitability, provided a suitable buyer for the digestate is found.

If the plant uses its own sludge as feedstock, the location of the biogas plant on the same plot is of course the most sensible solution to avoid logistical costs and emissions. On the other hand, if a centralised plant processing the side streams of several different producers is envisaged, the location should be considered in a way that minimises road transport.

The biogas plant project started in early 2020. A biogas consultant contacted them and wanted to present their partners' possible solutions for building a biogas plant in Pieksämäki. The preliminary studies concluded that it would be better to proceed in stages and first implement a plant using only the sewage treatment plant's surplus sludge.

The profitability of the project, the calculations were good.

The sludge has previously been transported to a biogas plant in Kuopio under contract.

I see it as very important.

The biogas plant project is the largest single project of its size that Pieksämäen Vesi has implemented.

So far I haven't had to, but the future will tell. For now, it seems that the facility can be managed internally.

The global situation has posed certain challenges for technology supply, but these have been overcome.

At the start of the project, the payback period was estimated to be around ten years. This will become more accurate once the actual return figures are known.

The facility will be maintained and serviced. The amount of biogas produced will be increased with various other fractions from outside the plant, such as grease sludge.

For more information:

Eero Tilsala, Biovoima

eero.tilsala@biovoima.fi

+358 40 514 7047

Tero Kemppi, Finnish Biovoima Oy

tero.kemppi@biovoima.fi

+358 50 4087100

"*" näyttää pakolliset kentät

© 2026 Biovoima

Privacy policy