Biovoima has provided biomethane logistics solutions, BIOlogistic CH4 - gas containers for its customer Sorpa in Reykjavik, Iceland. The project was completed ahead of schedule at the end of February 2024. Five gas containers were delivered to Sorpa by Biovoima.

High-pressure gas transfer tanks are a cost-effective solution when biogas is processed into biomethane and needs to be transported further away from the biogas plant for gas utilisation. Biomethane can be transported to industrial plants that use biogas for process energy production, for injection into the natural gas grid or for transport to a gas refuelling station.

Sorpa uses gas containers to transport biomethane to its industrial customers. Sorpa's mechanical and energy engineer Thorleifur Thorbjörnsson says the new containers will reduce transport costs by around 250 % due to higher gas capacity. The change will make logistics more efficient and will also have a positive impact on the environment by reducing emissions.

Four out of five gas containers are made of lightweight, low-cost fibreglass. These Type IV gas containers allow a large volume of CNG to be transported with minimum mass and safely. When compressed, the volume of gas is about 250-300 times less than atmospheric pressure. One of the five gas containers is based on steel cylinders. Type I high pressure gas transfer containers are the most economical investment option for short transport distances compared to lighter container solutions.

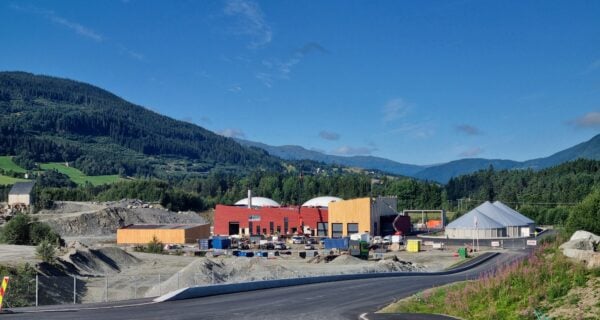

According to Thorbjörnsson, working with Biovoima has gone very well and he is happy to have found a partner who can take care of their needs in a holistic way. Sorpa's investments are in response to the rapidly growing demand for biomethane in Iceland, with industrial users in particular experiencing a strong increase in demand for biomethane. According to Þorbjörnsson, the Reykjavik region also has a high potential for biogas utilisation, not only because of biowaste but also because of the agricultural and fish industries. Sorpa is responsible for waste management in the Reykjavik area and currently operates the only biogas plant in Iceland. Sorpa has been a customer of Biovoima since 2022 and has already ordered similar solutions for biomethane transmission in the past.

SORPA is owned by six municipalities; Reykjavík, Kópavogur, Hafnarfjörður, Garðabær, Mosfellsbær and Seltjarnarnes. SORPA is responsible for waste management in the region and thus also fulfils the legal obligations of the municipalities. It includes the operation of a reception and sorting plant, a landfill, a gas and natural gas plant and six recycling plants operated under a service contract with the municipalities.

Jani Kangasaho

Sales Director, Partner

"*" näyttää pakolliset kentät

© 2026 Biovoima

Privacy policy