Biovoima's key principle is to act as a technology integrator. This means that the key to our customers' success lies in our choice of equipment for different process steps: what, why and how they work together. Decisions are always made on a project-by-project basis, based on the customer's budget and the performance levels to be achieved in the plant.

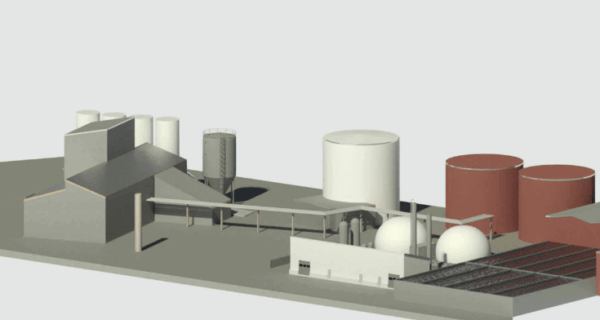

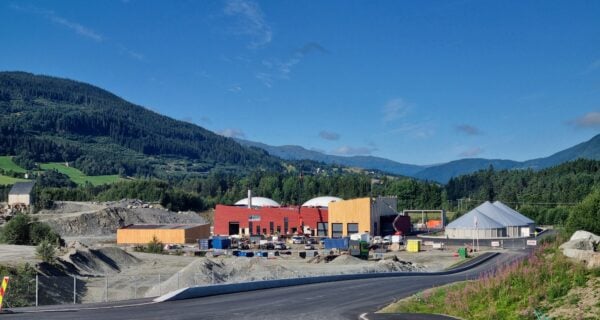

For the Voss plant, where the final customer is BIR AS - the largest waste management company in the Bergen region of Norway - the requirements were defined through a public tender.

Let's dive into the process itself!

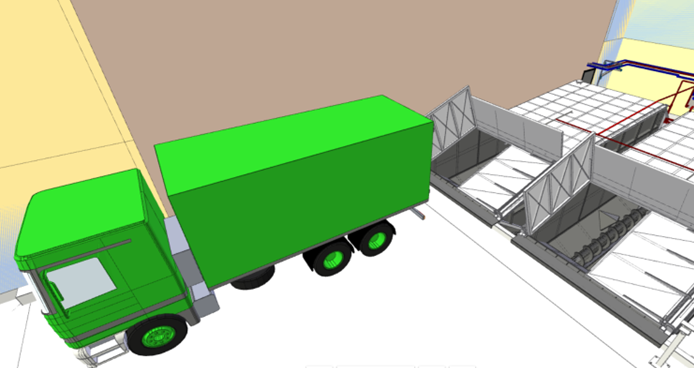

BIR delivers biowaste from households, restaurants and grocery stores to the biomethane plant in packer trucks and containers. In addition, liquid manure is received in tanker trucks directly from local farms. To prevent the spread of odours and to provide a more pleasant working environment for drivers, all waste is received indoors.

As the facility is located in an arctic climate, it is particularly important that the reception silos are robust enough to withstand the unloading of (more or less) frozen waste shipments. Seamless cooperation between the reception and pre-treatment facilities is also needed to ensure a stable feed of waste into the pre-treatment system and on to the biogas process.

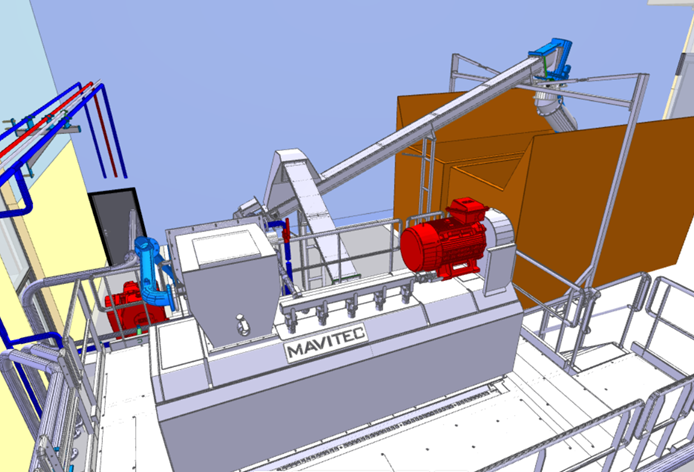

For this reason, all downstream equipment has been ordered from Mavitec Green Energy, a close partner of Biovoima. They have extensive experience in both waste reception and pre-treatment. This means we can be confident that there will be no frustrating bottlenecks at the initial stage of waste treatment.

As mentioned in the context of waste reception, waste pre-treatment is also handled by Mavitec technology. In practice, this means separating the organic fraction from the packaging materials, and then achieving the maximum particle size required for pasteurisation. The pre-treatment is carried out with a paddle mill, which is one of the best options when the aim is to:

After the pre-treatment stage, the organic sludge is pumped into a buffer tank where it is mixed with the slurry. After mixing, the feed is ready for the biogas process. The packaging materials are collected as high-quality RDF (refuse-derived fuel) in transport containers and sent to the BIR combustion plant for further energy production.

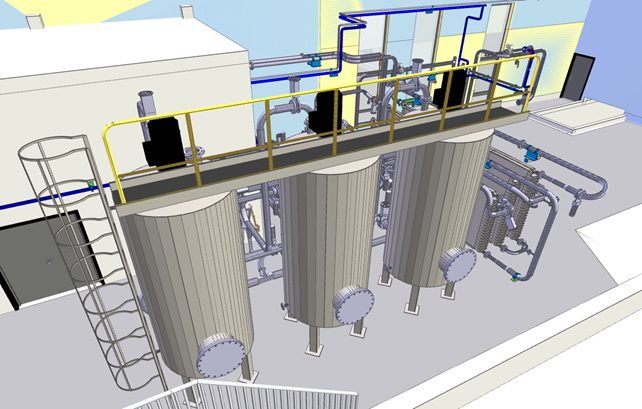

Sanitisation is an EU-required process where organic material is heated to 70°C for one hour to eliminate salmonella and other pathogens. This is necessary to ensure that the digestate can be used safely as fertiliser.

The hygienisation system at the Voss plant is a proprietary product of Biovoima, BIOpasteurizer - the so-called ”continuous input process”. In this process, one batch is prepared for an hour's stay, another is kept at 70 °C for an hour and the third is drained. This continuous operation optimises heat recovery.

In practice, the sanitation system consists of tanks, pumps, piping, valves and heat exchangers. With the right technical solutions, up to 70 % of the thermal energy used can be recovered. At the Voss plant, heat is recovered in two steps: first, the incoming material is preheated with heat from the reactors (~40 °C), followed by further preheating with the previous batch of pasteurisation (~70 °C). In this way, a high temperature is achieved even before the actual heating! This is achieved by unique slurry-slurry heat exchangers supplied by Westcome Heat Exchangers.

As the biogas plant is located close to a residential area, the odour gases from waste storage and treatment must be carefully cleaned before being released into the atmosphere. This is where Scandinavian Centriair AB's technology comes in. All major odour sources are equipped with a target extraction system, and this highly concentrated air is treated with different technologies selected according to the specific gases in each odour source. Before release into the atmosphere, the residual components of the odour gases are decomposed by a combination of activated carbon and UV reactors.

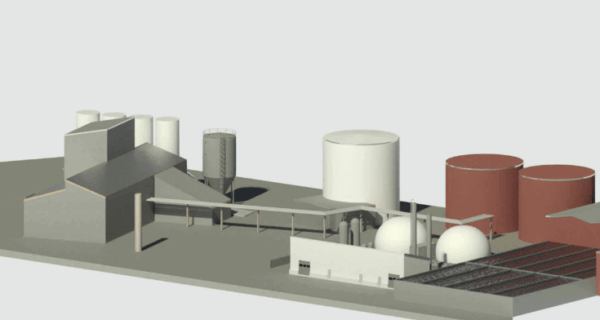

At the Voss biomethane plant, biogas is produced in Canada's Inova biogas reactors, using Schmack Biogas reactor technology. The uniqueness of Schmack's technology is based on the huge Remex mixers. These slowly rotating paddle mixers consume very little electricity, but still allow higher solids concentrations in the reactors compared to conventional wet digestion reactors (also known as CSTR reactors). This in turn reduces the heat consumption of the plant, as less water needs to be heated to the process temperature, which is typically around 40 °C.

Another feature of Schmack's reactor technology is the wooden ”false roof” structure, which forms a microfilm surface for the removal of hydrogen sulphide (H₂S). This allows about 50 % of the % of hydrogen sulphide generated to be removed already inside the reactor, reducing the need for investment in additional desulphurisation technologies such as activated carbon or scrubbers - especially from a maintenance point of view.

Once the organic matter in the waste has been converted into biogas, what remains is a wet, nutrient-rich sludge called digestate - or organic fertiliser. The digestate contains the same nutrients as its starting material (in this case 1/3 food waste and 2/3 cattle manure), but in a more hygienic and soluble (= better) form.

In the Voss project, biofertiliser is separated (as is often done) into a solid and a liquid fraction. However, the choice of equipment was influenced by the specific requirements of local farmers. In the Voss area, it is important to precisely control the amount of phosphorus applied to the field, so the separation technology was chosen primarily on the basis of the best phosphorus separation efficiency.

The separation process is enhanced by the use of an Alfa Laval decanter sterilizer. The lingo achieves a higher separation efficiency for phosphorus (solid fraction) and nitrogen (liquid fraction) compared to, for example, screw presses. This allows farmers to precisely control nutrients without the risk of over-fertilisation.

The biogas produced in biogas reactors is further refined into biomethane, i.e. cleaned from carbon dioxide (CO₂) and other gas components in a biogas purification system.

There are several different technical solutions for biogas cleaning. The four main technologies are water washing, amine washing, membrane technology and PSA (Pressure Swing Adsorption). Water scrubbing is a low-cost solution, but it carries risks related to the quality of the biomethane, especially in cold conditions. Amine scrubbing is the best option where there is plenty of extra heat available, but expensive for projects where this is not the case. The final selection included membrane technology and PSA, as the call for tenders required the lowest possible use of water and chemicals.

Although Biovoima has its own biogas upgrading technology based on membrane technology BIOupgradeCH4 ,The PSA system from Provedal was selected for the Voss project. Membrane technology is currently the most popular biogas processing method in the world and has an attractive investment cost but slightly higher electricity consumption. The higher the biogas flow rate, the faster the lower operating costs (less electricity and maintenance) make PSA more economically viable. As life cycle cost was the main criterion for the Voss project, the decision was tilted in favour of PSA. However, both produce the same high quality end product - biomethane.

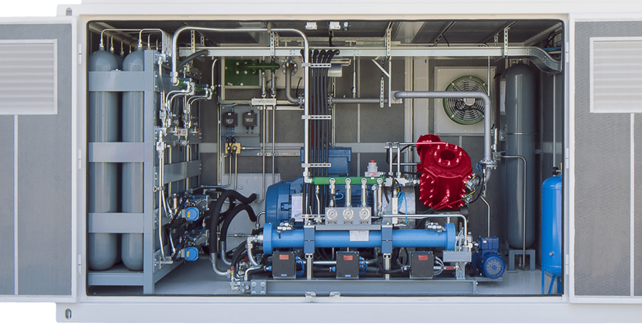

Once biogas has been processed into biomethane, its typical final treatment step is feeding into the natural gas grid, where it replaces fossil gas as a renewable alternative with similar properties. However, there is no natural gas network in the Voss area, so the gas has to be compressed to the smallest possible volume - either for cost-effective transport to industrial users in gas transport vehicles or to fuel BIR's own waste trucks.

This high-pressure (250 bar) methane compressor is supplied by Fornovo Gas of Italy, a market leader with more than 2 500 compressor installations. Fornovo Gas is also a long-standing partner of the Biovoima.

As mentioned earlier, the biomethane produced will be used as a 100% renewable fuel both in industry and in the waste vehicles of BIR and its partners. For industrial users, the gas is supplied in high-pressure in gas transporters. The plant's automation system accurately tracks the amount of gas filled into each container, which facilitates BIR's logistics and invoicing management.

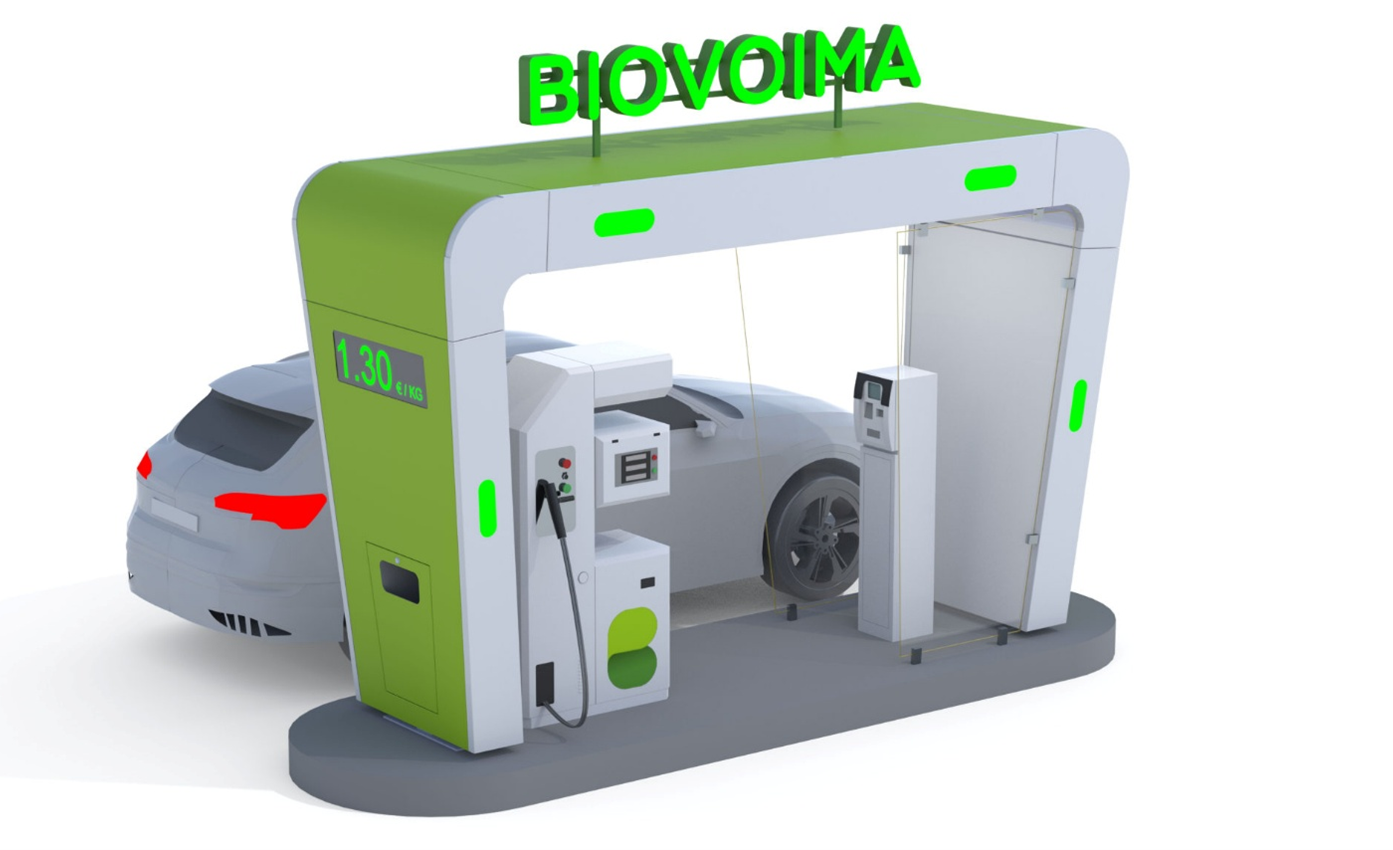

The same practical system also applies to the plant's own Biovoiman gas refuelling station, BIOparkia. For the driver, the refuelling process is as simple as at a normal petrol station. The price of the gas is automatically determined by the agreements between the BIR and the companies filling the tank. The gas is commonly known as CBG (compressed biogas), which is chemically equivalent to CNG (compressed natural gas), but as a renewable and environmentally friendly alternative.

To ensure seamless operation between several different pieces of equipment, the automation system must meet high standards. As Valmet Automation has experience in the world's most complex biorefineries, it was chosen to provide the ”umbrella system” for the entire Voss biogas plant. High user-friendliness combined with Finnish quality, excellent safety and easy integration of different subsystems were the key criteria for Valmet's selection.

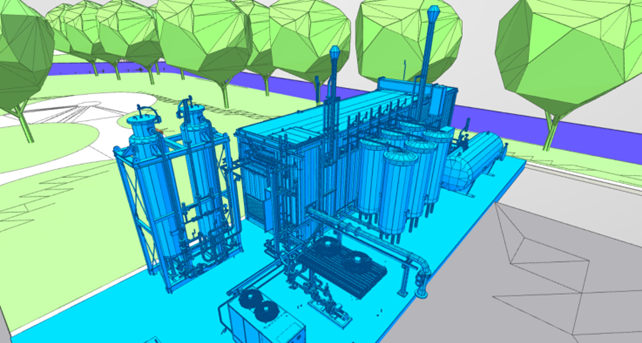

The Voss biogas plant is the first of its kind in Vestland County, Norway. It will produce biogas from biowaste collected from the region and manure from local farms. The plant has a total treatment capacity of 54 000 tonnes of organic waste per year. Most of the biofertiliser produced in the process replaces the use of cattle manure as fertiliser, significantly reducing methane emissions and odours from agriculture. Thanks to the improved fertiliser properties, this can also reduce the need for fertiliser imports.

The biomethane produced at the plant is mainly used as a fuel for BIR's heavy-duty vehicles and as an environmentally friendly alternative to fossil natural gas and liquefied natural gas (LNG) in the industrial sector in the Voss area. A gas refuelling station is also planned in the centre of Voss to make use of local biogas. Vehicles will literally run on energy from local biowaste and cattle manure - a great example of the practical application of the circular economy!

Biovoima is proud and happy to be part of this project!

Jani Kangasaho

Sales Director, Partner

Tero Kemppi

Project Manager

+358 50 408 7100

"*" näyttää pakolliset kentät

© 2026 Biovoima

Privacy policy